Frac Hit Mitigation

Frac hits are costing operators billions of dollars in lost production. This article introduces a new treatment method to mitigate the effects of frac hits and to increase production in initial as well as infill wells. This patented treatment method uses fluid in combination with highly surface-modified nanoparticles. The combination provides a temporary high-stress fracture environment in the initial well to prevent neighboring fracture interactions using the fluid. The highly surface-modified nanoparticles act to reduce interfacial tension, modify wettability, and disjoin and fragment hydrocarbons to create a favorable fluid-flow environment to enable increased and sustained production.

Frac Hits

As development of unconventional reservoirs continues with tighter and tighter well spacing, some of the current production and subsequent reserves of the initial well are often compromised. In many cases, the initial well consists of large, permeable fracture networks connecting to much tighter matrix reservoir rock. By the time the infill well is drilled, the initial well in the spacing unit may have already produced several hundred thousand barrels of fluid.

This depletion often creates a lower-stress environment around the induced fractures of the parent well — in other words, a pressure sink may form predominantly in the fracture network. As an infill well is drilled and completed, the initial well will become more vulnerable to an intersection from a nearby propagating fracture leading to severe production losses. In addition, fracture fluid and proppant communication may occur between the neighboring wells, also leading to an ineffective stimulation of the infill well. As the name — frac hit — suggests, a powerful force is unleashed that can also result in severe damage to production tubing, casing, and well heads.

Infill wells often demonstrate production performance of 60% or less when compared to the existing initial well. Initial well interference can include undesirable increases in water production, as well as oil production decreases that frequently do not return to their previous levels. Numerous causes have been cited, including stress reversal, tendency of infill well fractures to grow toward initial well fracture networks, and improper well spacing. It has been reported that the longer the initial well has been on production, the higher the likelihood of an induced stress change, resulting in a higher probability of infill well interference. Negative influences can be seen in the form of fines migration, proppant migration, or fluid pressure communication between the infill well frac zone to the initial well frac zone, and vice-versa.

Current Strategies

With intense pressure from c-suites and investors to cut costs and increase production, hydraulic fracture interference or frac hits are an increasing problem in today’s more mature unconventional fields. Operators must develop strategies to combat production losses caused by frac hits.

Refracturing has been explored as a potential solution, however there are limitations when it comes to the cost-effectiveness of this process. A more economic strategy currently employed is re-pressurizing the initial well prior to fracturing the infill well. Re-pressurizing the initial well consists of using a fluid to fill the depleted fractures and the voided pore spaces around these fractures. While the pressurization effect is temporary, as an offset well is fractured nearby, the temporary higher-stress environment near the initial well fractures works to prevent well-to-well fracture interaction — protecting the initial well’s productivity.

The images below show the pressure depletion and re-pressurization process in an initial well.

A typical 1,280-acre spacing unit is represented above. The solid black line is an existing well and the black dashed line is a new well drilled and being prepped for initial fracture stimulation. The smaller hatched lines represent natural fractures in the unconventional reservoir rock.

Provided the initial well has produced 250,000 reservoir barrels of total fluid, the dark color represents pressure depletion associated with drainage along the fractures.

To mitigate the effect of the drainage of the initial well, both on the fracture efficacy on the new well and on the continued production of the initial well, water is injected into the original or initial wellbore. The water fills the high perm fractures reducing the effects of drainage.

nanoActiv® — A Unique Solution to Frac Hits

The method of pushing nanoActiv® by fluid to mitigate frac hits is a patented well-additive treatment and method — mechanically powered by highly surface-modified silicon dioxide particles. nanoActiv® is made in Houston, Texas, by Nissan Chemical America Corporation (NCA), a division of Nissan Chemical Corporation founded in Japan in 1887. A forerunner in chemical innovations for more than 130 years, Nissan Chemical Corporation has been perfecting nanoparticle technology since 1951 — making it one of the first companies in the world to produce highly surface-modified colloidal particles for industrial applications.

nanoActiv® Technologies

nanoActiv® Technologies are designed to penetrate deep into the reservoir and persist with long efficacy.

nanoActiv® HRT (Hydrocarbon Recovery Technology)

Through Brownian motion, nanoActiv® HRT deploys what is known as “disjoining pressure”, a phenomenon that suggests nanoparticles lift hydrocarbons from the rock surface at the three-phase contact angle. nanoActiv® surrounds hydrocarbon drops, fragmenting them into smaller droplets, enabling efficient flow back to the wellbore. nanoActiv® particles exhibit substantial persistence and remain within the matrix and natural fracture network after contact flow-through — facilitating ongoing improved hydrocarbon mobility.

nanoActiv® EFT (Enhanced Flowback Technology)

nanoActiv® EFT is an Enhanced Flowback Technology. nanoActiv® EFT is a nanoparticle micellar dispersion stabilized using a synergistic combination of distinctive highly surface-modified silica nanoparticles, a soy-bean extract solvent, and a blend of surfactants. It exhibits an extremely effective primary chemical action enhanced with the added mechanical properties of Nissan Chemicals’ nanotechnology. nanoActiv® EFT delivers the unique advantages of diffusion, disjoining pressure, fragmentation, and interfacial tension reduction for improved stimulation fluid interaction within the reservoir near the created and propped fracture facies, as well as throughout the entire propped fracture network — increasing initial oil and gas production.

nanoActiv® Frac Hit Mitigation Technology

Nissan’s frac hit mitigation process begins when nanoActiv® is deployed into the initial well during the re-pressurization process. nanoActiv® HRT or EFT is injected as pills or intermixed with a total volume of injected fluid. While the added fluid provides the benefits of a temporary high-stress barrier near the initial well, the nanoparticles provide the benefit of significant IFT reduction, as well as wettability modification near the well-bore to create a much more favorable fluid-flow environment. Consequently, not only are fracture interactions mitigated, more hydrocarbons are also produced.

nanoActiv® and High Shear Fractures in Infill Wells

This is the plague of the Permian now: not only are initial wells getting crushed by offset fracs, the infill wells themselves aren’t producing up to expectations. nanoActiv® Frac Hit Mitigation Technology is a key change element in improving production results of these closely spaced shale horizontal wells.

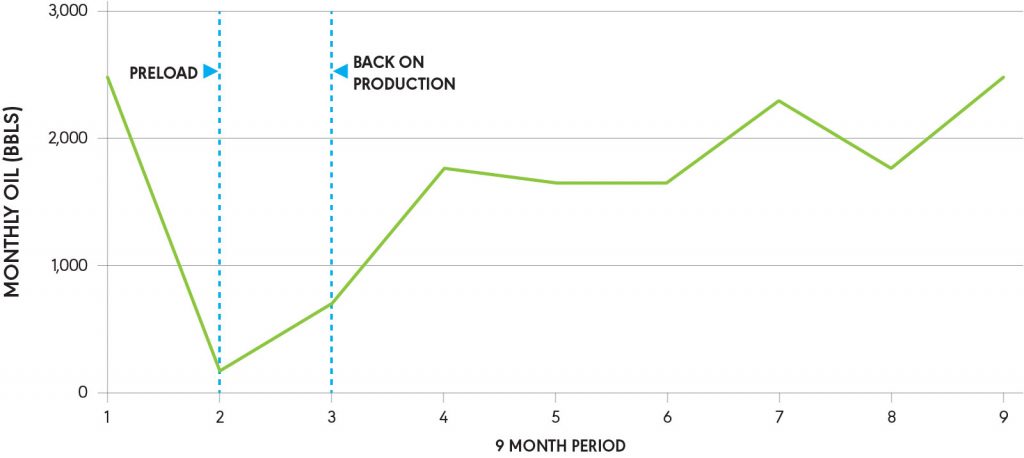

nanoActiv® is successful in boosting both initial and infill well results. On a recent job in the Permian Basin, Shear Frac Group LLC, measured the type and amount of fractures created per second on the infill pad with their proprietary technology, Frac BRAIN™. The infill well closest to the nanoActiv® preloads showed a significant increase in the cumulative fracture count compared to the other adjacent infill wells on the pad. Shear Frac’s engineer explained that normally infill wells have lower fracture counts due to offset depletion, however this was not observed in this well. Frac BRAIN™ is a real-time, cloud-based tool which easily links to the frac data van to help operators guide hydraulic fracture inputs and improve fracture surface area creation during operations. This technology provides a new measurement of rock failure and fracture efficiency using surface pumping data to determine the amount of shear (complex) or tensile (planar) fractures created. Engineers from the operator believe the reason the initial preload was so effective with nanoActiv® is because the small size (12-15 nm) of the surface-modified nanoparticles in the fluid caused the preload fluid to access parts of the tight rock that normal fluid wouldn’t enter — saturating the rock near the infill well. Combine that with a pressure barrier and lowering of the surface tension of the preload fluid by the components of nanoActiv® EFT, and you get optimal infill fracturing. Add to this the fact that the nanoActiv® preloaded initial wells returned to oil production less than 10 days after coming online (one recent well is exceeding previous production amounts within the first week) and the operator is enthusiastically proceeding to target future pads as nanoActiv® preload candidates.

nanoActiv® in the Field

nanoActiv® has been pumped in various initial well pre-load jobs across the Eagle Ford, Anadarko and the Permian basins. The first case study presented consists of a treatment of 5,000 gallons of nanoActiv® injected as smaller volume pills throughout the initial well pre-load for a well in Dewitt County in the Eagle Ford. The treatment was allowed to soak for approximately 2.5 weeks during the infill well work to allow the nanoparticles in nanoActiv® to diffuse out into the reservoir, and to alter the wettability of the formation to create more favorable fluid-flow conditions.

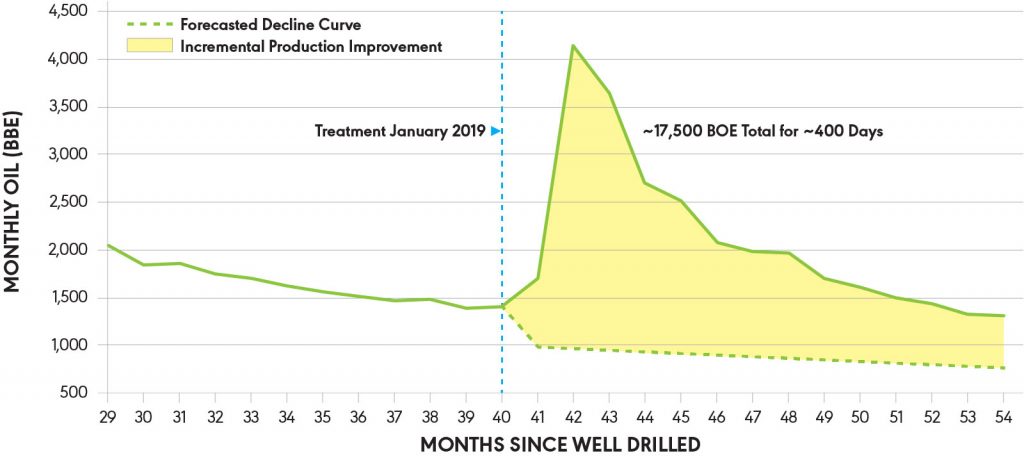

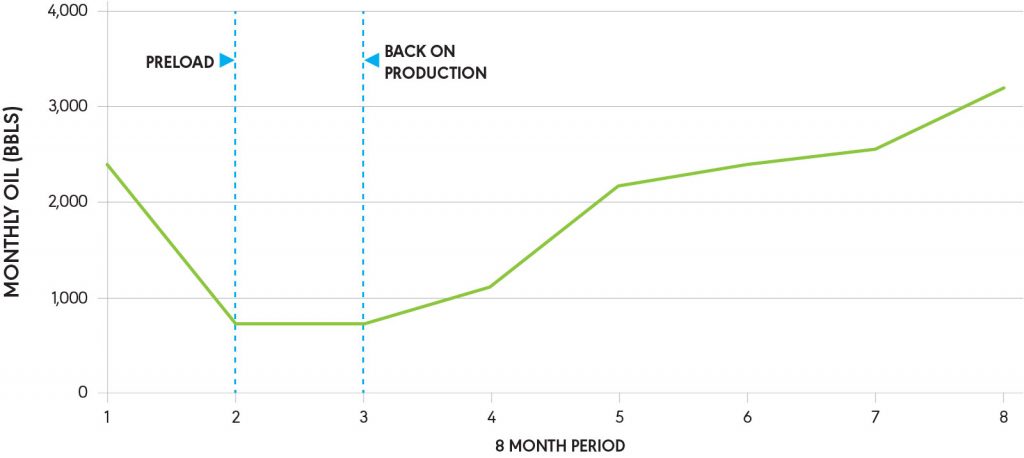

For Well A, a significant increase in monthly oil production has been observed post-treatment where the pre-load treatment has surpassed the previous production rate for more than 6 months.

Well B shows the case history of the second initial well pre-load treatment using nanoActiv® in Dewitt County in the Eagle Ford. Again, 5,000 gallons were used for the treatment, with a soak time of approximately 2.5 weeks. A significant increase in production can be seen for up to four months post-treatment.

Well C shows production data from a third well in Dewitt County, TX, in the Eagle Ford. For this well, 2,500 gallons of nanoActiv® pills were injected throughout the initial well pre-load with a similar soak time as stated above. Similarly, to Well B, a significant increase in production can be seen for up to four months post-treatment.

The second case study presented shows the production data for two wells in Grady County, OK, in the Mississippian formation in the Anadarko Basin.

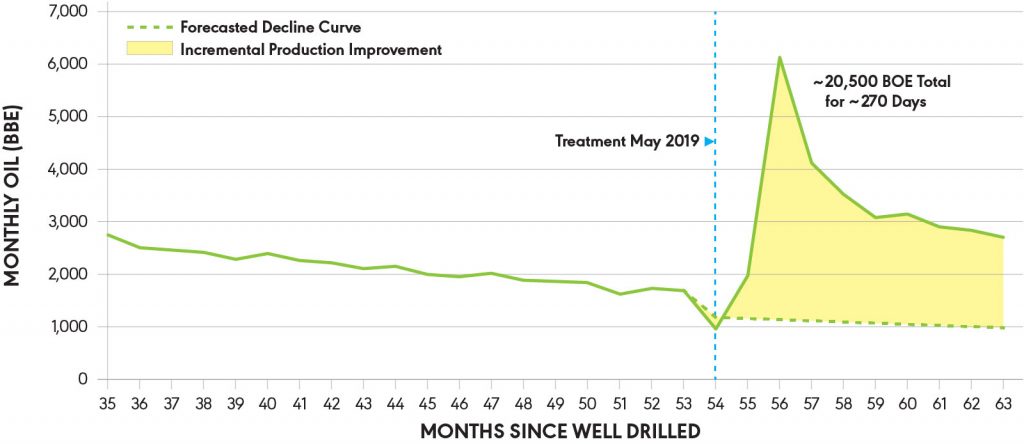

Well A consisted of a 17,000-gallon treatment of nanoActiv® pills pumped intermittently throughout the initial well pre-load. The production data trend seems to demonstrate an almost reversed trend in the production losses caused by the frac hit after treatment with nanoActiv®.

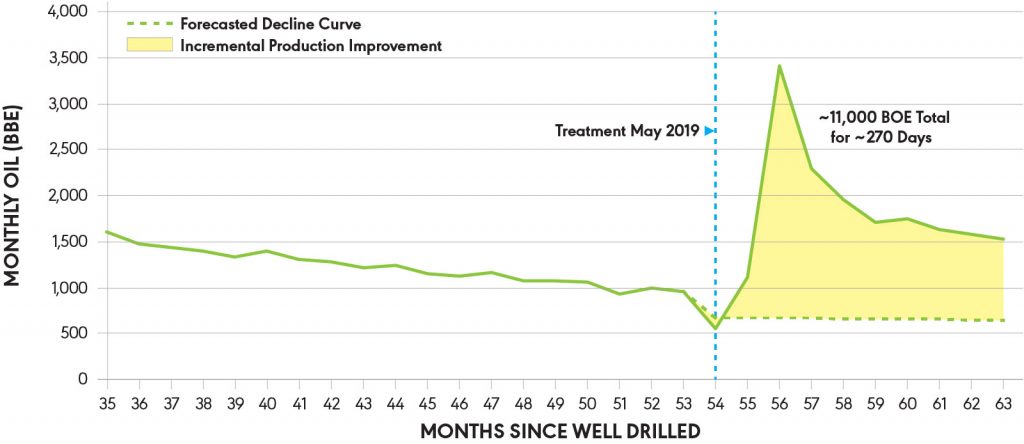

A very similar trend is observed in Well B, also in the Mississippian formation where the treatment volume of nanoActiv® was only 4,500 gallons nanoActiv® pumped throughout the preload job with approximately 2.5 weeks soak time.

Conclusion

Currently, frac hits cost the industry billions of dollars a year in lost production. The effects of frac hits can be significantly mitigated by the patented process of combining a re-pressurization fluid with nanoActiv® (highly surface-modified nanoparticles). nanoActiv® Technologies work to reduce interfacial tension and modify wettability — allowing more hydrocarbons to be mobilized in a re-pressurized environment created using large volumes of injected fluid. Consequently, not only are frac hits mitigated, but more hydrocarbons are also produced — increasing production and profitability.

nanoActiv® is made in the USA · Patented in the US and other countries